Over the last three months, we ran a study of SoterAI users across 34 organizations in the US — from manufacturing to logistics to construction. We wanted to understand where safety leaders actually spend their time.

The results weren’t surprising, but they were sobering: most safety managers lose 10–15 hours every week to administrative tasks. That’s time spent chasing corrective actions, updating training records, building inspection schedules, and packaging audit evidence — instead of reducing risk or engaging with frontline teams.

The good news: these hours can be reclaimed. By focusing on the right processes first, and then layering in light automation, safety teams can save the equivalent of a full workday every week.

In this article, we’ll share the five biggest time-suckers our study uncovered, how much time they drain, and how you can start cutting them down in just 30 days.

What our study revealed

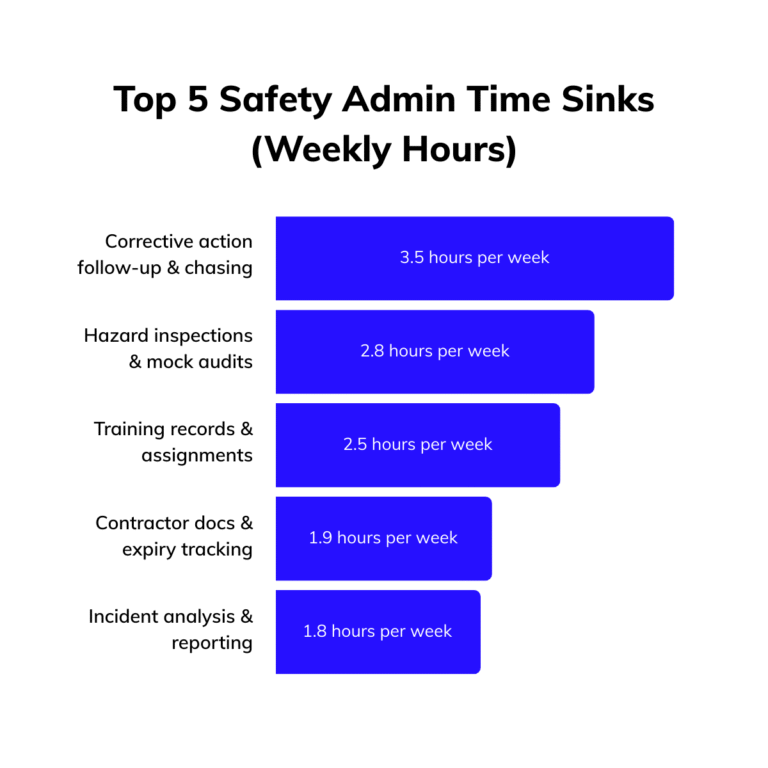

In our three-month study of 34 SoterAI user organizations across the US, we found that five recurring admin tasks consistently consumed the most time. Together, they account for ~12.5 hours per week — nearly a day and a half of lost productivity for every safety manager.

These are the bottlenecks where effort goes in but impact is low. They’re also the clearest candidates for process improvement and light automation.

1. Corrective action follow-up & chasing (~3.5 hrs/week)

Emailing owners, reminding supervisors, and collecting proof of fix take longer than fixing the hazards themselves. Many actions stall because there’s no clear SLA or escalation path.

Opportunity: Automate reminders, enforce photo/document proof before close, and add an escalation ladder for overdue items.

2. Hazard inspections & mock audits (~2.8 hrs/week)

Building inspection schedules, prepping checklists, and adjusting for asset/site changes eats time every cycle. Manual prep also increases the chance of missed hazards.

Opportunity: Use standardized digital checklists with conditional sections and automated scheduling.

3. Training records & assignments (~2.5 hrs/week)

Maintaining spreadsheets, enrolling new hires, and tracking refresher deadlines is tedious and error-prone. One missed record can derail compliance.

Opportunity: Shift to role- and risk-based assignment rules, with automatic refresh cycles.

4. Contractor documentation & expiry tracking (~1.9 hrs/week)

Collecting insurance, safety docs, and certifications — then re-checking expirations — turns into endless email chains.

Opportunity: Contractor portals with self-upload and automatic 30/7-day expiry reminders reduce the chasing.

5. Incident analysis & reporting (~1.8 hrs/week)

Turning frontline reports into structured events, tagging severity/site, and packaging updates for leadership takes significant admin time.

Opportunity: Guided intake forms and instant distribution briefs cut hours out of the loop.

From wasted hours to reclaimed time: the 30-day plan

Why a 30-day plan works

You don’t need to overhaul your entire safety management system to make a difference. We worked with the teams to come up with a simple plan of action that most can action within a month.

Week 1: Spot the waste

Before you can reduce safety admin time, you need to see where it’s going.

- List your recurring tasks: inspections, corrective actions, training, contractors, incidents.

- Track how many hours go into each for one week (rough estimates are fine).

- Highlight the two biggest drains — they’ll be your starting point.

Outcome: A clear picture of where most of your time is being lost.

Week 2: Target your biggest time wasters

AI delivers the biggest returns when applied to repetitive, predictable admin work. Once you’ve mapped your time, the next step is deciding which processes to automate first.

- Rank your tasks by hours wasted: Start with the one or two workflows that consume the most time.

- Look for repeatable patterns: Corrective actions that always require follow-up, inspections that always need prep, training assignments that always get delayed.

- Define the “trigger” and the “finish line”: Example — trigger: a corrective action logged; finish line: proof-of-fix uploaded and verified.

- Clarify ownership paths: Which person/role normally owns each step? This lets AI route tasks without confusion.

Don’t try to automate everything at once. Focus on 1–2 areas where the gains will be obvious.

Outcome: You know exactly which workflows to automate — and what “done” looks like in each.

Week 3: Apply automation to the obvious

This is where hours start to come back.

- Corrective actions: Automatic reminders, overdue escalations, and proof-of-fix checks.

- Inspections: Auto-scheduling, checklist generation, and recurring hazard flags.

- Training: Role-based assignments, refresher scheduling, and record updates.

- Contractors: Expiry tracking, 30/7-day reminders, and document validation.

- Incidents: Convert free-text reports into structured records and send instant notifications.

Outcome: The repetitive admin loop starts running itself, freeing up hours every week.

Week 4: Lock in adoption and show results

The final step is making the change stick — and proving the value.

- Nominate champions on each site/shift to support adoption.

- Run micro-training — short refreshers instead of long workshops.

- Publish a monthly safety brief — AI can generate a simple report with the 5 most important metrics (actions closed, inspections completed, training compliance, contractor status, incidents reported).

- Compare Week 1 vs Week 4 metrics: Hours saved, overdue tasks reduced, compliance scores improved.

Outcome: A sustainable new system that saves 6–10 hours a week and demonstrates ROI to leadership.

How to measure success in 30 days

A 30-day plan only works if you can show it made a difference. The good news is you don’t need complex dashboards — just a few simple metrics will prove the value.

Key metrics to track:

- Admin hours saved

Compare your Week 1 time estimates to Week 4. Even reclaiming 2 hours per person per week adds up to 100+ hours a year. - Corrective actions closed on time

Measure the % of actions closed within SLA. AI-driven reminders and proof-of-fix requirements should move this sharply upward. - Inspections completed as scheduled

Track the completion rate of planned inspections — automation should push this closer to 100%. - Training assignment coverage

Look at the % of modules assigned automatically vs manually. More automation = less spreadsheet work. - Contractor compliance

Monitor how many contractors have expired documents at any given time. The number should fall as auto-reminders take hold.

Framing results for leadership:

- Time → “We reclaimed X hours per week of safety staff time.”

- Compliance → “We cut overdue corrective actions by Y%.”

- Risk reduction → “We increased on-time inspections to Z%.”

Together, these show both productivity gains and safer outcomes.

Want to reduce your admin load?

Talk to our team and see how automation can save you hours every week.